Product Discription

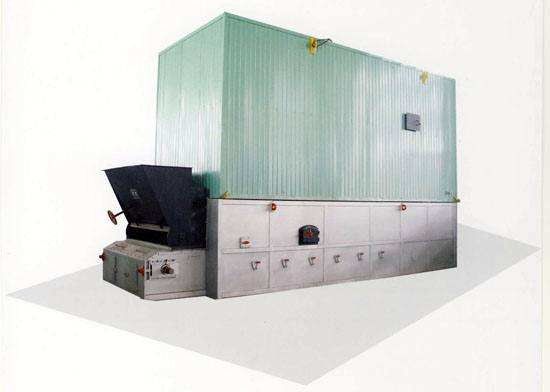

YLW Series Horizontal Chain Grate Biomass Thermal Oil Boiler

1. The serial organic heat exchanger YLW is a square network heat exchanger with a forced circulation current. It consists of the upper part of the body (or upper part of the body) and the lower part of the body and is placed on the site. The body of the furnace uses unique or double replacement pipes. The tail is equipped with an air heater, a steam heater and a hot water saver. the fences used by the user can be recovered from the waste heat, the waste heat temperature can be reduced, the thermal efficiency can be improved, fuel consumption can be reduced and energy can be stored.

2. Organic heat boilers are unique industrial boilers that use coal, heavy oil, oil and gas as fuel, high temperature oil as a heating port, circulating pump as heat transfer unit and heat transfer oil, can be returned to the heating and heating furnace This is a new type of energy conversion device. Its main advantage is high temperature and low pressure (atmospheric pressure or low pressure).Pressure, stable operation, wide USO range.

Product Features

1. Easy removal of ash:

The installation of a suction blower in a convective boiler heat transfer area can quickly and efficiently remove the soot, prevent the impact of accumulation by reducing boiler operation or thermal efficiency and ensure the stability of boiler load.

2. High security:

It is controlled by a computer and is equipped with protection against hot oil and oil shortages, temperature and pressure protection equipment that is safe and reliable.

3. Long life and sustainability:

Excellent technical design, advanced production technology, strict quality control and control are the quality assurance of each boiler. The normal life span of the boiler is more than twenty years.

4. Environmental protection and low noise:

The emissions of flue -gas from the boiler are low, with the recovery of waste heat, a high -efficiency dust collector, a low -noise fan, so that the flue -gas emission meets national environmental protection requirements.

5. Standard production:

The boiler components are manufactured in accordance with national and international standards (ISO); all processes take consistent account of advanced production technology to ensure product quality.

6. Good service:

Technical consultations, technical services, installation instructions, regular and irregular follow -up services for users, at any time to provide quality and complete services to ensure that customers buy and use safely.

Technical Parameters

Main Technical Parameters of YLW Series Biomass Heat Carrier

| Item |

Unit |

YLW-1000T |

YLW-1400T |

YLW-1900T |

YLW-3000T |

YLW-3500T |

YLW-4600T |

YLW-7000T |

| Thermal Power |

KW |

1000 |

1400 |

1900 |

3000 |

3500 |

4600 |

7000 |

| Heating Load X104 |

Kcal/h |

80 |

120 |

160 |

250 |

300 |

400 |

600 |

| Working Pressure |

MPa |

1.0 |

1.0 |

1.0 |

1.0 |

1.0 |

1.0 |

1.0 |

| Rated oil output temperature |

℃ |

300 |

300 |

280 |

300 |

300 |

320 |

320 |

| Rated oil return temperature |

℃ |

280 |

280 |

265 |

280 |

280 |

295 |

300 |

| Thermal Efficiency |

/ |

≥79 |

| Fuel |

/ |

Fuel |

| Fuel Consumption |

Kg/h |

242.7 |

364 |

484 |

756.7 |

910.4 |

1208.7 |

1813.2 |

| Heating area |

m2 |

64.8 |

108.4 |

198 |

212 |

245 |

304.8 |

399.4 |

| Grate area |

m2 |

2.02 |

3.7 |

4.92 |

5.32 |

6.23 |

8.5 |

11.8 |

| Main engine oil capacity |

m3 |

0.65 |

0.71 |

2.8 |

3.4 |

4.35 |

4.94 |

7.6 |

Note: the fuel consumption in the table is calculated on the basis of the low calorific value of biomass particles 17084KJ/Kg (4085Kcal/Kg). If the low calorific value of biomass fuel is larger than this value, the corresponding fuel consumption will be more economical than the value in the table.

| Item |

Unit |

YLW-1000T |

YLW-1400T |

YLW-1900T |

YLW-3000T |

YLW-3500T |

YLW-4600T |

YLW-7000T |

| Thermal Power |

/ |

KW |

1000 |

1400 |

1900 |

3000 |

3500 |

4600 |

7000 |

| Heating LoadX104 |

Kcal/h |

80 |

120 |

160 |

250 |

300 |

400 |

600 |

| Maximum Part Transport Dimension |

L |

mm |

4400 |

5500 |

6380 |

5720 |

6470 |

6460 |

7040 |

| W |

mm |

2200 |

2650 |

2990 |

2990 |

2840 |

2980 |

3240 |

| H |

mm |

3150 |

3410 |

3780 |

3100 |

3100 |

3720 |

3300 |

| Oil Outlet Pipe Diameter |

DN |

mm |

65 |

125 |

125 |

150 |

200 |

200 |

250 |

| Oil Return Pipe Diameter |

DN |

mm |

40 |

125 |

125 |

150 |

200 |

200 |

250 |

| Exhaust Pipe Diameter |

DN |

mm |

2*25 |

2*25 |

25 |

25 |

25 |

2*25 |

2*25 |

| Drain Valve Pipe Diameter |

DN |

mm |

2*25 |

2*25 |

25 |

25 |

40 |

2*25 |

2*25 |

| Chimney Diameter |

φ |

mm |

280 |

350 |

420 |

450 |

530 |

530 |

800 |

Remarks: We will reserve rights to change the above mentioned data due to continuous policy transformation and product improvement.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!