Product Description

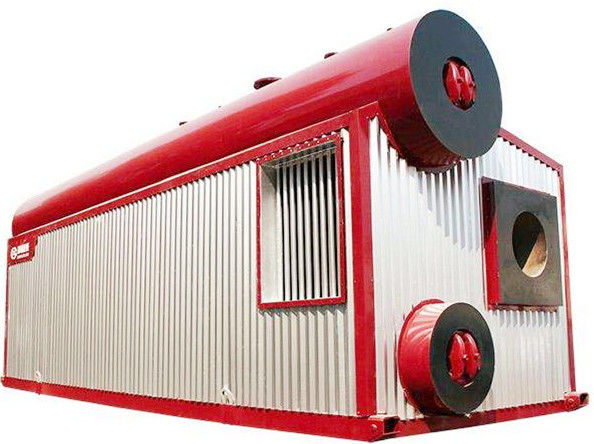

SZS Series Double Drum Oil and Gas Fired Hot Water Boiler

Gas vapour boilers with double drums of the SZS series are two drums, long -running, fast -charging water heaters. The series of boilers consists of upper and lower drums, membrane walls, convection tubes and capacitors. Fuel burns in the boiler. The flue gas is discharged into the chimney from the convection pipes and the waste heat.

Product Feacture

1. Advanced control system:

Fully automatic control, users only need to press the start button, the boiler can be set up after the program to start operation. Load control and automatic water supply are all automatic operations that meet the needs of users.

2. In accordance with environmental requirements:

The Furnac area is large and it is equipped with imported high quality and reliable quality burners so that the fuel can be fully burned and harmful components in the flue -gas are significantly reduced. The inspection by the relevant departments shows that our petroleum products meet the strictest national environmental protection requirements and meet national environmental protection requirements. Continuous improvement of environmental requirements.

3. Different fuels:

Furnace area is large, fuel combustion is sufficient, especially suitable for low -calorific fuels such as coke oven gas, blast furnace gas, etc. natural gas, liquefied gas, etc.

4. Reasonable structure:

It is easy to repair the burner head by installing the front water balance in front of the boiler, which ensures the water level and cooling near the burner, and helps to remove the carbon stock in the burner and make the fuel burn more fully.

5. Easy to maintain:

The explosion -proof door, fire -proof hole and inspection door are mounted on the wall of the boiler and the man -made door is mounted on the front and back of the boiler to facilitate inspection of the boiler.

Technical Parameters

| Main technical parameters of SZS series pressure cushion water boilers |

| Item Type |

SZS7 |

SZS10.5 |

SZS14 |

SZS21 |

SZS29 |

SZS35 |

SZS42 |

SZS46 |

| Rated Heat Efficiency |

MW |

7 |

105 |

14 |

21 |

29 |

35 |

42 |

46 |

| Rated Working Pressure |

MPa |

1.0/125 |

L0/L25 |

1.0/1^5 |

1^5/1.6 |

125/L6 |

1-25/1.6 |

L25/L6 |

1.25/16 |

| Rated Effluent temperature |

°C |

115/130 |

115/130 |

115/130 |

115/130 |

115/130 |

115/130 |

115/130 |

115/130 |

| Return water temperature |

°C |

70 |

70 |

70 |

70 |

70 |

70 |

70 |

70 |

| Efficiency |

/ |

>96% |

| Design Fuel |

/ |

Natural gas, liquid gas, city gas, light oil

Liquefied gas,

City Gas

Light oil

|

|

Fuel

Theoretical consumption

|

gas |

NM3/h |

731 |

1097 |

1462 |

2191 |

3026 |

3657 |

4383 |

4799 |

| Liquid gas |

Kg/h |

586 |

877 |

1169 |

1755 |

2421 |

2928 |

3511 |

3843 |

| City Gas |

NM3/h |

1572 |

2354 |

3138 |

4705 |

6503 |

7839 |

9149 |

9991 |

| Light Oil |

Kg/h |

599 |

899 |

H93 |

1801 |

2479 |

2989 |

3601 |

3943 |

| Natural gas |

mbar |

150-200 |

150-300 |

150-300 |

150-300 |

150-300 |

150-300 |

150-300 |

150-300 |

| City gas |

mbar |

150-200 |

150-300 |

150-300 |

150-300 |

150-300 |

150-300 |

150-300 |

150-300 |

| Rated water circulation |

M³/h |

133/100 |

200/150 |

266/200 |

400/300 |

551/414 |

665/500 |

798/600 |

874/657 |

Note: The fuel consumption in the table is calculated by low calorific value of light oil 42915KJ/Kg (10260Kcal/Kg), low calorific value of natural gas 35588KJ/NM3 (8500Kcal/NM3), low calorific value of liquefied gas 45998KJ/Kg (11000Kcal/Kg), low calorific value of urban gas 16750K/NM3 (4000Kcal/NM3).

| Configuration and Interface Dimensions of SZS Series Pressure Overlay Boilers |

| Item |

type |

SZS7 |

SZS10.5 |

SZS14 |

SZS21 |

S2S29 |

SZS35 |

SZS42 |

SZS46 |

|

Host transport dimensions

(length * width * height)

|

/ |

mm |

5633*33

00*3400

|

6365*35

85*3478

|

8781*36

25.383

|

Separate transportation |

Separate transportation |

Separate transportation |

Separate transportation |

Separate transportation |

| Host Weight |

/ |

t |

150/200 |

200 |

200 |

300 |

300 |

350 |

350 |

400 |

| Outlet Valve Diameter |

DN |

mm |

150/200 |

200 |

200 |

2*200 |

2*200 |

2*200 |

2*200 |

2*300 |

| Backwater Valve Diameter |

DN |

mm |

50 |

50 |

2*50 |

2*50 |

2*50 |

2*50 |

2*50 |

2*50 |

| Atmospheric Connecting Pipe Diameter |

DN |

mm |

750 |

1000 |

1100 |

1400 |

1700 |

2000 |

2000 |

2200

|

Note: Due to the continuous updating of products, the company reserves the right to modify the data in the above two tables.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!